The process of ionization consists in exposing the products to be treated with the gamma radiations emitted by a source of Cobalt 60.

Gamma Rays

The emitted photons have two energy levels: 1,17 and 1,33 MeV.

Note: Energy levels higher than 10 MeV are required to induce radioactivity in the exposed product.

Therefore, gamma ray photons are of too low energy to induce any radioactivity in the treated products.

These gamma rays allow the sterilization of medical material, cosmetic and pharmaceuticals products.

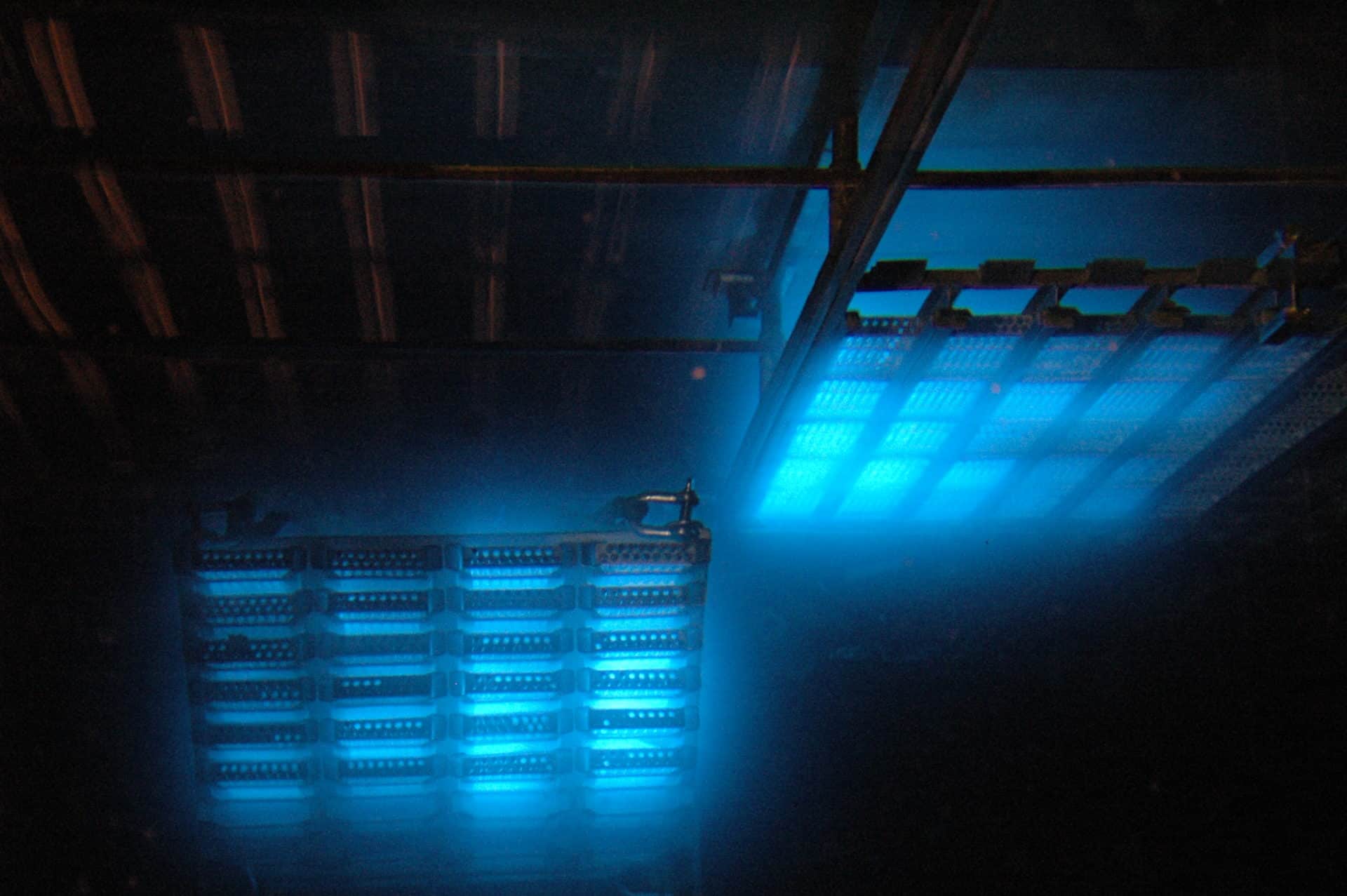

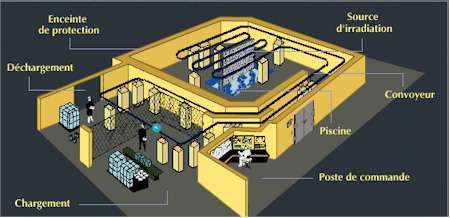

During the time products are being treated, the source is maintained raised in the air in the centre of the treatment cell. When product treatment is not required, the source is lowered into the pool of water. The water functions as a radiological shield.

An automatic system of conveyors moves the products into the irradiation cell, passing the product close to the radiation source according to a predefined route and at a specified speed, before leaving the cell following the treatment.

- the activity and configuration of the source,

- the distance between the source and the product,

- duration of irradiation,

- the composition and density of materials.

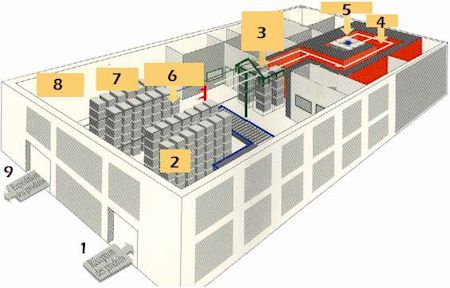

Pallet irradiation

Location : Sablé sur Sarthe and Pouzauges

- Product reception

- Acceptance inspection

- Automated pallet loading and unloading

- Labyrinth

- Ionization unit

- Automatic storing system

- Storage of the irradiated products

- Predispatch inspection

- Product dispatching

Tray conveyor irradiation

Location : Dagneux.

Nearly half a century of basic and applied research have shown that ionising radiation is both safe and effective and it is guaranteed and recommended by the World Health Organisation and the Food and Agriculture Organisation.

A SAFE AND PRACTICAL PROCESS

The treatment process is performed in accordance with the following rules:

- the product stays in its packaging (no subsequent recontamination)

- no temperature rise (heat sensitive, refrigerated or deep-frozen products)

- no quarantine, so the products are available immediately at the end of treatment, thus reducing storage costs.